Technologies

Technologies

The data storage industry caters to the ever rising demand of our rapidly increasing digital footprint. We depend on magnetics to store and subsequently retrieve the vast amount of information used by the computing industry and data centers. Magnetic recording employs the use of 'hard' magnetic materials to store information. Hard magnetic materials require strong magnetic fields to orient the direction of magnetization within the material. These materials, once oriented, permanently and reliably retain this magnetic orientation until they are reoriented by another subsequent magnetic field.

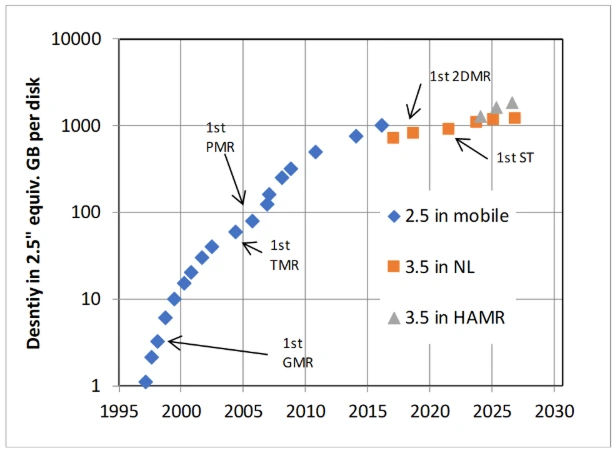

The primary technology aim of the data storage industry is to be able to pack more bits on the same media surface area for each generation, allowing reduced cost per stored Terabyte for our customers. TDK Headway Technologies is the only independent manufacturer of recording heads that are used to write and read back the hard magnetic disks that store the data. Shown below is the density progression in one form factor (2.5” disk), illustrating that we delivered more than 1000-fold density increase in a period of 20 years. Besides scaling down the head and advancing the head structures and materials, a key enabler for this has been the introduction of new technologies such as GMR (Giant MagnetoResistive) reader, TMR (Tunneling MagnetoResistive) reader and PMR (Perpendicular Magnetic Recording) writer.

Capacity of a 2.5” and 3.5” NL disk vs market introduction date (all in 2.5” disk equivalent capacity

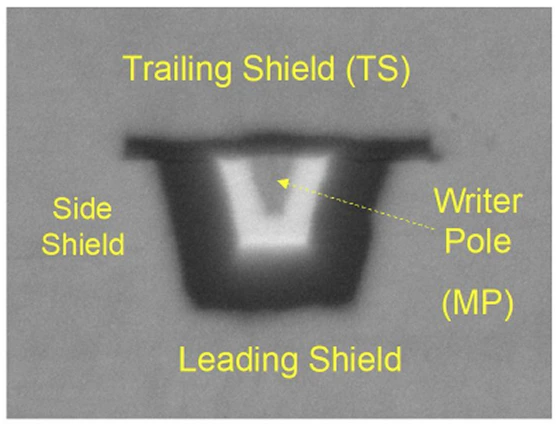

Magnetic Recording Industry transformed into Perpendicular Magnetic Recording (PMR) where stored bits are oriented perpendicular to the media surface. Headway and its customers were among the first to introduce this technology to the marketplace in 2004. PMR allows a much higher density of bits compared to its predecessor- Longitudinal Magnetic Recording (LMR). As the head continued scaling down and improving its structure, recording densities also kept on advancing. Shown below is a typical PMR head as seen from the recording surface. Similarly in 2005, Headway was also among the first to introduce TMR which allowed significant progress in how the written bits are read back with much higher signal to noise ratio (SNR). Higher SNR yielded higher recorded linear (downtrack) densities.

PMR Write Head as seen from the recording media. Slanted edges of the writer pole allow writability through the skew range of the drive.

TMR Read Head: Reader Film (free layer) and reference layer are separated by a thin insulator known as the tunneling barrier. The head exhibits a large difference in its electrical resistance between reading an “up-bit” and reading a “down-bit”

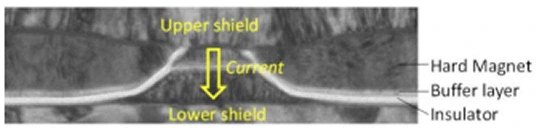

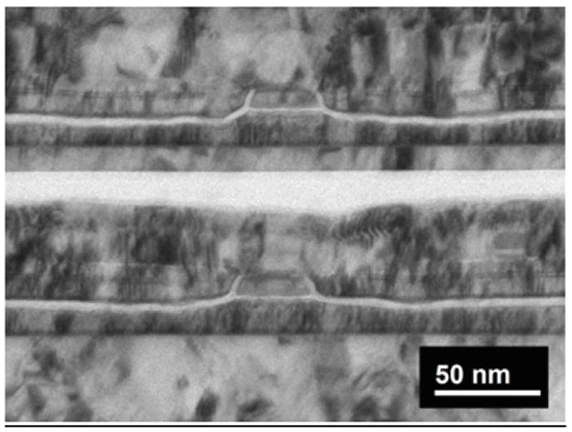

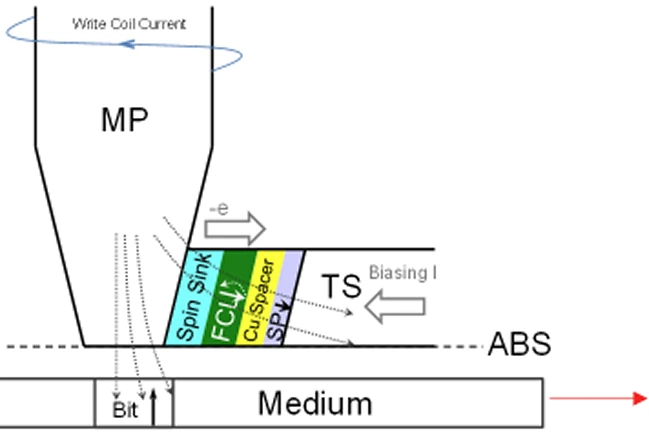

In 2017 we started providing industry's first 2DMR (two dimensional magnetic recording) heads to our customers. 2DMR allows two readers to read the same data sequentially while taking advantage of the noise cancellation of the second reader that may be on the adjacent track. A TEM of our first generation 2DMR-TMR reader is shown below. In 2021 Headway introduced industry’s first spin-torque (ST) assisted writer. In this structure, an ST element is inserted between the pole and the return shield whose magnetic orientation responds to the current and the magnetic polarity of the main pole. This technology is presently in use in CMR drives, ultimately approaching 2.8 TB per 3.5” platter.

2DMR head showing two TMR read elements in close proximity downtrack

Spin Torque Element introduced into the write gap of a PMR recording head. MP=write pole, TS= trailing shield, → media travel

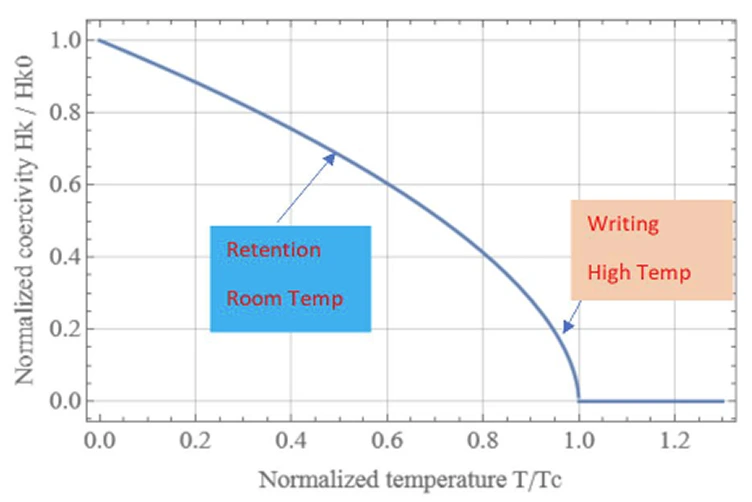

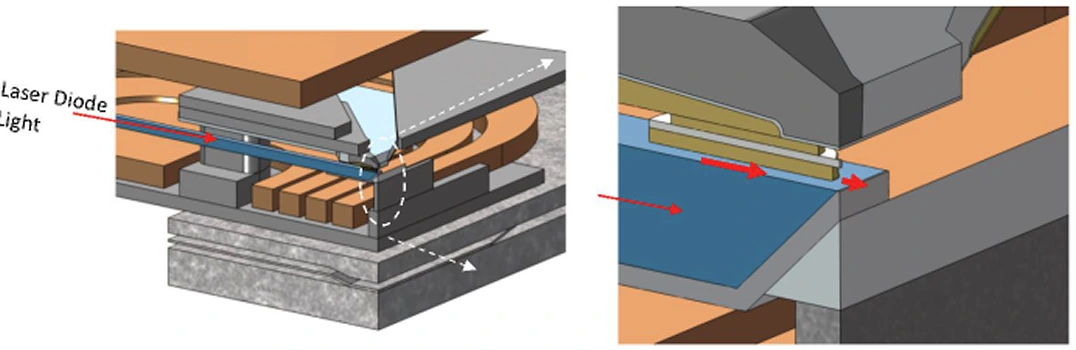

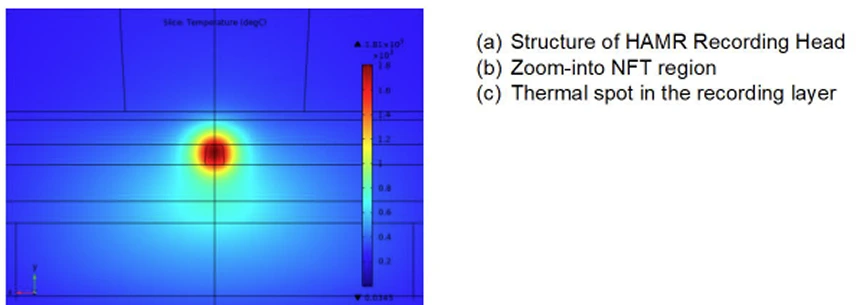

As dimensions scale, it becomes harder to write a narrow track as the writer pole gets smaller following the track density. To overcome this challenge, media coercivity can be reduced for a very short period of time just for the purpose of writing with coercivity quickly restored to its room temperature value for long term data retention. Similar to others in our industry, Headway has been involved in developing a HAMR (Heat Assisted Magnetic Recording) head for the past 15 or so years. The technology has now advanced to the point where we are currently qualifying our heads in customer drives towards achieving more than 30 TB per drive (equivalent to >3 TBpp). HAMR is based on using optically induced heating to drop the media coercivity for a short period to record the data. Shown in below figure is the dependence of media coercivity on temperature. Recording is performed at elevated temperature while the data is retained at room temperature.

HAMR head adds a near field optical transducer and a light delivery path to a conventional PMR head. These features allow optical spots as narrow as 20 nm to be generated on the disk surface. This would allow track densities exceeding 1 million tracks per inch. Incoming optical power is provided by a laser diode directly mounted on each head element.

As a proud technology innovator for the recording industry for the past 31 years, TDK Headway team is committed to inventing and developing cutting edge technologies to continue providing value to our customers by extending the amount of data storable on a disk with no compromise on head reliability and data integrity. The ever growing appetite for more data storage ensures that our creativity will continue to find a home in future HDDs.